Application Specific Analyzer

Our top-quality analyzers cater specifically to each industry’s needs. With a wide range of cutting-edge products, we ensure accurate and

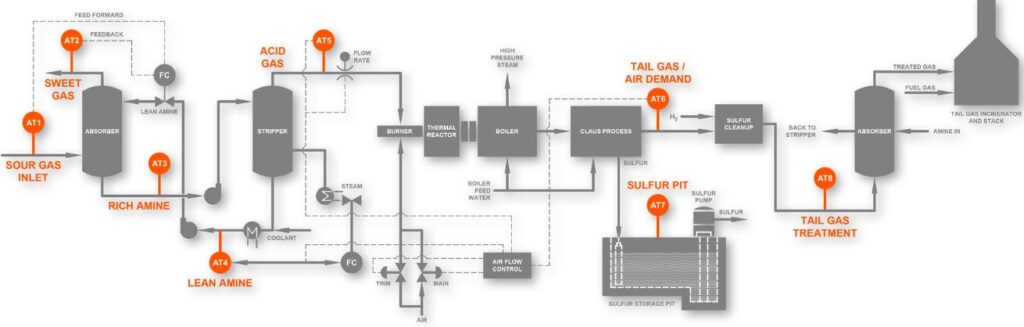

Hydrogen sulfide (H2S) is a byproduct of processing natural gas and high-sulfur crude oil, exposures to H2S with a concentration greater than 500 ppmv can be fatal. This extremely dangerous byproduct must be closely monitored and the amount of H2S released to the atmosphere must be minimized that is why Sulfur Recovery Plant are used to convert (H2S) in an incoming gas stream into elemental sulfur.

We offer a range of analyzers based on Ultra-violet Visible Spectroscopy for high-quality analysis at various points in Sulfur Recovery Plants including:

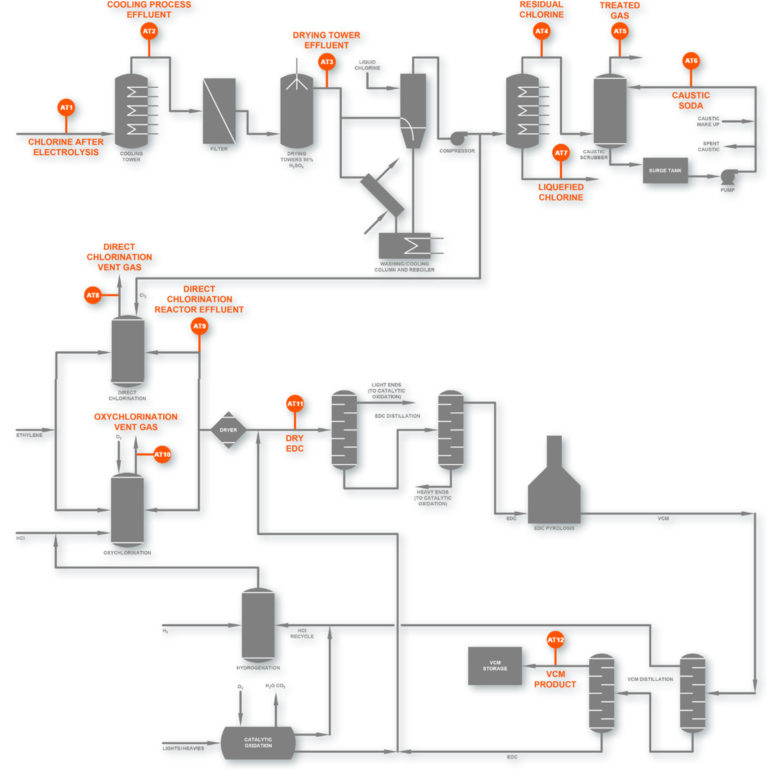

Chlor-alkali refers to the production of Chlorine (Cl2), sodium hydroxide/caustic soda (NaOH), and hydrogen gas (H2) from the electrolysis of saltwater. Both chlorine and hydrogen gases are used for a multitude of different operations in the chemical industry such as the production of VCM. Sodium hydroxide is ubiquitous in the chemical and oil/gas industries, with applications ranging from sulfur removal from low grade crude oil, to the production of food and soap.

We offer a range of analyzers based on Ultra-violet Visible Spectroscopy for high-quality analysis of each stage of the process:

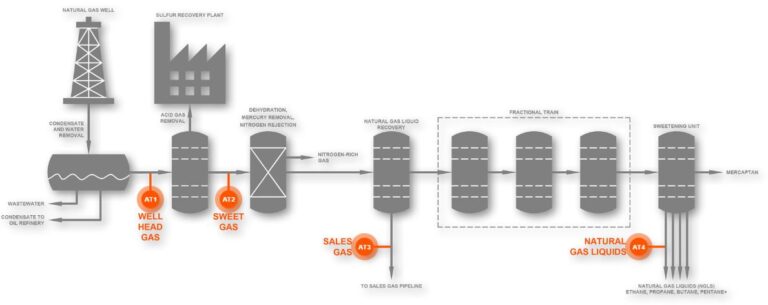

From wellhead to main, We provide trusted solutions for monitoring natural gas composition. Flagship products include multi-component odorant monitoring, hydrogen sulfide measurement, carbon dioxide measurement, BTEX analysis, and saybolt readings.

Our top-quality analyzers cater specifically to each industry’s needs. With a wide range of cutting-edge products, we ensure accurate and

Various industrial processes require continuous monitoring of chlorine compounds’ concentrations for healthy operation. The connecting concern between all these applications

We offer an analyzer which provides extremely reliable sample color analysis; this system is an ideal colorimeter for hydrocarbon fuel

We offer a Hydrocarbon dew point analyzer which combines the established water dew point measurement and the hydrocarbon dew point

We offer an analysis module that operates based on the principle of thermal conductivity. It is optimized for the measurement

H2S occurs abundantly in the world’s fossil fuel reserves and also forms as a by-product in various industrial and biological

We offer a high-quality, multi-channel fiber optic hygrometer for measuring the moisture and trace humidity in gases and liquid. The

We offer the world’s safest tail gas analyzer which continuously measures the concentrations of H2S, SO2, COS, and CS2 in

Sulfur compounds–particularly hydrogen sulfide–in natural gas carry with them a host of problems and considerations for both producer and consumer.

Presence of Moisture in many applications as per its chemistry prove to be the worst enemy and may cause catastrophic

Potentia brings together technology and engineering to produce a world of solutions for the benefit of out customers.

© All rights reserved by POTENTIA

Our team will reach you out in 1-2 working days