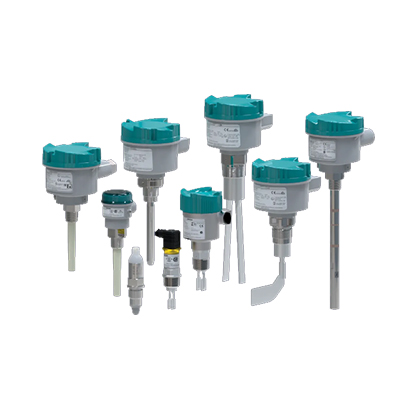

Continuous Level Measurement

The continuous eyes and years of your operations. Processes in your facility are constantly changing -so you’d better know what’s

The best in class inverse frequency shift approach to RF capacitance technology ensures accurate, reliable and repeatable measurement even in dusty, turbulent and vaporous environments or in situations with product build up. Because even a small level change creates a large and detectable change in frequency, our devices provide excellent resolution while consistently outperforming conventional devices.

Our vibrating level switches are perfect for detecting high, low and demand levels in liquid or solid applications including materials with extremely low bulk density. With options for high temperatures, extreme pressures and remote testing, these switches provide solutions for most industries. Our vibrating level switch can detect a solid interface within liquid. Featuring potted electronics and a robust design for aggressive applications including heavy external vibrations.

Capacitance Instruments are contacting level and interface devices for measuring liquids and some solids. Inverse frequency change technology delivers high resolution, fast reaction time and consistently accurate measurements of even the smallest level changes in short spans or in materials with a low dielectric constant. With simple two button start up and extremely low maintenance and recalibration needs, capacitance technology will save you time and money. Our capacitance interface level switch is ideal for standard and industrial applications in chemical, hydrocarbon processing and food and beverage industries and can handle those difficult applications where emulsion and rag layers are challenging.

Guided Wave Radar is a contacting technology that excels in monitoring interface of the liquids and also provide accurate level measurement. Advanced echo processing gives unmatched reliability and accuracy when measuring level and interface in everything from small to large vessels. Extreme conditions like high pressure and temperature are no problem for these transmitters

The continuous eyes and years of your operations. Processes in your facility are constantly changing -so you’d better know what’s

Whether measuring levels of two materials in a storage vessel or telling your control system when to separate one liquid

Level gauge indicators are devices used in the measurement of the level of fluids in various industrial applications. These devices

Your plant’s lifeline to safety, efficiency and a headache-free day. Precision and reliability are of top priority in level measurement.

Potentia brings together technology and engineering to produce a world of solutions for the benefit of out customers.

© All rights reserved by POTENTIA

Our team will reach you out in 1-2 working days