Continuous Level Measurement

The continuous eyes and years of your operations. Processes in your facility are constantly changing -so you’d better know what’s

Radar Level Measurement is a non-contacting technology built for monitoring levels of both liquids and solids. Challenging process environments like vapor, pressure, dust or high temperatures are no match for these instruments. Process Intelligence, the transmitter’s advanced method of processing echo profiles, guarantees reliable and accurate level measurement and automatically ignores the obstruction. The different variations available include:

Guided Wave Radar is a contacting technology that excels in monitoring the level of liquids and solids. Advanced echo processing gives you unmatched reliability and accuracy when measuring level and interface in everything from small to large vessels. Extreme conditions like high pressure and vapors are no problem for these transmitters. Unlike traditional guided-wave radars that use device parameters requiring multiple adjustments, our Guided wave radar level transmitter does it for you. The instrument uses built-in intelligence to differentiate between the actual level and other false signals. Guided wave radar uses very low power microwave energy to determine the level or interface of products being measured. Our specialized guided wave radar level transmitter cover a wide range of applications. They can meet your needs for applications up to 200 °C and 200 bar and that too in certification with SIL2 and SIL3.

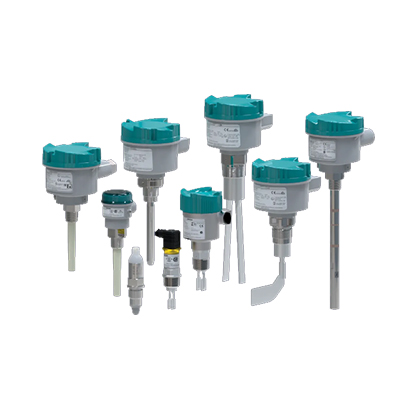

Capacitance instruments are contacting level and interface devices for measuring liquids and some solids. Inverse frequency change technology delivers high resolution, fast reaction time and consistently accurate measurements of even the smallest level changes, in short spans or in materials with low dielectric constant. With simple two button start up and extremely low maintenance and recalibration needs, capacitance technology will save you time and money. Our Capacitance Continuous Level Transmitter is an inverse frequency shift capacitance transmitter for liquids and solids or liquid interface applications. Materials with low or high dielectric properties are accurately measured and Active Shield technology helps in preventing build up near vessel nozzle and is ideal for standard industrial applications in chemical, hydrocarbon processing, food and beverage, water, waste water, mining, aggregate and cement industries.

Our comprehensive product portfolio for hydrostatic transmitter in Continuous Level measurement range includes direct measurement or remote seals. Hydrostatic level technology can handle extreme chemical and mechanical loads as well as electromagnetic interference. Cable versions allows for installation in small tubes as well as over long ranges. This technology made of stainless-steel housing and piezo resistive sensor with ceramic membrane is widely applied in environmental, chemical and petrochemical industries and is suitable for tanks, channels and dams as well as for drinking water systems

Ultrasonic level measurement is a world leading non-contacting technology for measuring the level of liquids and solids. Our process intelligence separates true echoes from false ones. Using field proven algorithms to provide intelligent processing of echo profiles, our transmitters delivers superior performance every time. Our specialized ultrasonic level transmitter is capable of measuring liquid level or solid applications up to 50ft/15 meters or flow rates in all types of open channel flow applications. The transmitter has a single 4-20mA DC analog output with HART 7 and five relay outputs.

The continuous eyes and years of your operations. Processes in your facility are constantly changing -so you’d better know what’s

Whether measuring levels of two materials in a storage vessel or telling your control system when to separate one liquid

Level gauge indicators are devices used in the measurement of the level of fluids in various industrial applications. These devices

Your plant’s lifeline to safety, efficiency and a headache-free day. Precision and reliability are of top priority in level measurement.

Potentia brings together technology and engineering to produce a world of solutions for the benefit of out customers.

© All rights reserved by POTENTIA

Our team will reach you out in 1-2 working days