Viscosity Index Process Analyzer

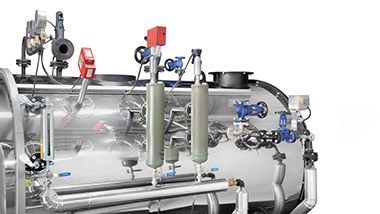

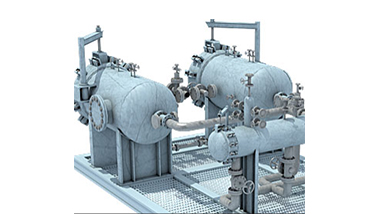

The viscosity of petroleum fluid gives an indication of resistance to flow. The viscosity index in this regard is an extensively used term to measure the variation in kinematic viscosity due to changes in the temperature. A higher viscosity index indicates a smaller decrease in kinematic viscosity with increasing temperature of the product. We offer the ASTM compliant viscosity index analyzer continuously and directly measuring Kinematic Viscosity with an integral measurement of density along with Integral calculation of viscosity index.

Recent Comments