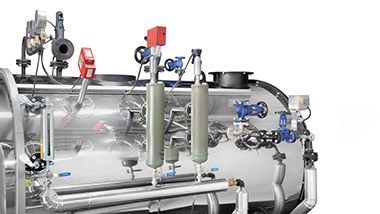

Particle-Liquid Separation Element

Compared to conventional cartridge filters, our solution saves money by lowering operating costs and reducing disposal costs. When comparing filters with the same efficiencies or Beta ratings, nothing outperforms the cost/performance value achieved the element.

With the existing conventional filter in place– pleated, depth, molded or string wound, nominal or Beta rated – these elements can replace the existing without modifying the external housing. Whether it is for water, amines, chemicals, hydrocarbons, oils, coolants, inks, paints, or other fluids, for pre-filtration or final filtration, i.e. either it is a new filtration application, or upgrading and optimizing a conventional cartridge filter application, the element is the right choice.

Recent Comments